Liquid Fuel Fired Thermic Fluid Heaters

Liquid Fuel Fired Thermic Fluid Heaters Specification

- Type

- Liquid Fuel Fired Thermic Fluid Heater

- Material

- Mild Steel

- Storage / Tankless

- Storage

- Installation Type

- Vertical / Horizontal

- Capacity

- 1,00,000 Kcal/hr to 30,00,000 Kcal/hr

- Voltage

- 415 V

- Power

- Diesel / Furnace Oil / LDO

- Dimension (L*W*H)

- Customized as per capacity

- Gas Type

- Diesel / Furnace Oil / LDO

- Tank Diameter

- Standard / As per design

- Color

- Black / Blue / Custom

- Safety

- Inbuilt with safety interlocks and safety relief valves

- Thermic Fluid Flow Rate

- As per design; consult datasheet

- Chimney Outlet Size

- As per model capacity (consult manufacturer)

- Fuel Consumption

- Depends on capacity; refer to technical brochure

- Control System

- PLC based fully automatic control panel

- Burner Type

- Pressure Jet Type

- Application

- Heating systems for process industries, textiles, chemical, pharmaceuticals, and food processing

- Max Operating Temperature

- 300C (572F)

- Mobility

- Stationary unit

- Flue Gas Outlet Temperature

- Approximately 180C 220C

- Efficiency

- Up to 88% (on Net Calorific Value)

- Heat Exchanger Material

- Seamless Tube, IBR Approved

- Firing Type

- Fully Automatic

Liquid Fuel Fired Thermic Fluid Heaters Trade Information

- Minimum Order Quantity

- 1 Unit Piece

- Delivery Time

- 7-10 Days

- Main Domestic Market

- Chandigarh, Himachal Pradesh, Nagaland, East India, West India, Assam, Arunachal Pradesh, Bihar, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Kerala, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Haryana, South India, North India, Andhra Pradesh, Central India, Odisha, Chhattisgarh, All India

- Certifications

- ISO 9001:2008

About Liquid Fuel Fired Thermic Fluid Heaters

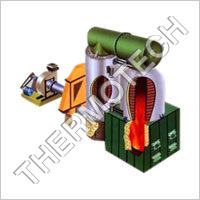

Thermic Fluid Heater Liquid and Gas Fuel Fired

Thermic Fluid Heater's are obtainable in Vertical and Horizontal Models where in thermic liquid can be heated about normal 340 degree Celcius at near environmental pressure with competence as greater as 92% on GCV of Gas and Oil fuel.

- Thermic Fluid Heater Volume = 0.1 MKcal/hr -15 MKcal/hr

- Supreme Temperature = 370 Deg. C

Application:

- Textile, Chemical, MDF and Particle Board, Technical Textile, Oil & Gas, Plywood and Laminates, Packaging, Pharmaceuticals, Rubber, Food Processing, Metal, etc...

- Fuel to Handle : LDO, Diesel, Furnace Oil, LPG, Hydrogen, N. Gas, etc..

- Quality Assurance: ISO 9001 : 2008 for more than 7 years.

Thermic Heater - Gas Oil / Fired Burner

THERMIC FLUID HEATERS are obtainable in VERTICAL and HORIZONTAL MODELS where thermic fluids can be heated to about normal 340 degree Celcius at near environmental pressure with competence as huge as 92% on GCV of Gas and Oil fuel.

The Main Heat Exchanger is integrated with a combined combustion chamber formed using High Heat Resilient Steel Tubes : BS 3059 P-1 and Seamless Pipes : SA106 GrB S40 of passable size, clearly designed with identical concentric multi twitch helical coil. This Coil is introduced into M.S. Shell with constructions provisions to place whole assembly leveled.

The system has 3 passes on flue gas side that safeguards optimal heat transfer with security current flow code. The combustion chamber is made to uphold safe distance amid coil tube surface and burner flame, that safeguards long thermic fluid life, optimum heat transfer because of lesser film temperature and security of helical coil tube that eventually defenses the complete heat exchanger.

HORIZONTAL UNIT WITH EXTERNAL AIR PRE HEATER

This innovative "HT" sequence of Thermic Fluid Heater : Thermic Fluid Heater Coal Wood Fired

"THERMOTECH" presents a novel vertical four passes THERMIC FLUID HEATER is suitable for Indian industries in fast changing and unreliable energy circumstances. The vertical design joined with integral furnace offers you an oath of a valued production on any solid fuel like wood, husk, coal, bagasse, etc. Our generous design assistances in exchange from one fuel to another deprived of negotiating on performance. Its quality promise product comes from THERMOTECH, the corporation recognized for its know-how of heaters and boilers all over India. Nowadays there are more than 1000 THERMOTECH fittings in the country almost in all kinds of industry dipping time and cost.

EFFICIENCY AT ITS PEAK

- Reduced Excess Air

- Radiant heat exchanger overhead furnace, cools henceforth, less extra air is required. This gives growth to efficiency.

- Air Preheating

- Combustion air from FD fan permits using air preheater to engage the left-over heat from the fuel gases. This outcomes in additional increase in efficacy.

- Balanced Draught System

- This system safeguards least infiltration of undesirable air via fire doors. Henceforth, all the combustion air permits via the APH. Therefore, the supreme heat retrieval from APH takes place, that safeguards rated efficiency.

- Rated Output

- Thermotech's vertical heater model provides you valued efficiency and its considered output.

- Multifuel Option

- The system is appropriate for wood, coal, bagasse etc. for complete production with minor alterations in combustion chamber.

Fuel Consumption control founded on gross calorific value:

- Lignite Coal: 3500 kcal / kg.

- Steam Coal: 4500 kcal / kg.

- Agro - Waste: 3300 kcal / kg.

High Efficiency & Versatile Applications

Achieving up to 88% efficiency on net calorific value, this thermic fluid heater is engineered for use in process industries including textiles, chemicals, pharmaceuticals, and food processing. With advanced control features and robust safety mechanisms, it delivers precise, reliable heating tailored to demanding operational needs.

Advanced Automatic Operation

The system is managed by a fully automatic PLC-based control panel, allowing seamless operation and monitoring. Integration of safety interlocks and relief valves ensures secure functioning, while automated controls minimize manual intervention and enable consistent performance.

Custom Configuration & Durability

Constructed with high-grade mild steel and seamless tubes, the heater is designed for longevity and optimal heat transfer. Various models and capacities are available, matching your unique requirements for installation space, fuel type, and operational preferences. Each unit is crafted for maximum reliability and performance.

FAQs of Liquid Fuel Fired Thermic Fluid Heaters:

Q: How does the fully automatic PLC-based control system enhance the operation of the thermic fluid heater?

A: The PLC-based control system ensures efficient and reliable performance by automating temperature regulation, burner operation, and safety functions. This reduces manual intervention, improves response times, and heightens operational safety, resulting in consistent heating with minimal user input.Q: What are the primary benefits of using a liquid fuel fired thermic fluid heater in process industries?

A: These heaters offer high thermal efficiency (up to 88%), flexible fuel options (diesel, furnace oil, LDO), and robust safety features. They maintain uniform heating, support a wide operating temperature range, and are suitable for various applications needing precise temperature control, making them ideal for process-intensive sectors.Q: Where can these thermic fluid heaters be installed, and are they available in different configurations?

A: These heaters are suitable for installation in factories, industrial plants, and production facilities across India. They can be configured in either vertical or horizontal orientations and customized in size, capacity, and color to match space constraints and operational requirements.Q: What is the recommended process for selecting the right capacity and model for my application?

A: Identify your desired heating load and process requirements. Consult the technical brochure or contact the manufacturer to assess fuel consumption, flow rates, and design parameters. The supplier can help determine the most appropriate model based on your applications specific needs.Q: When is IBR approval necessary, and does this heater comply?

A: IBR (Indian Boiler Regulations) approval is required for pressure vessels in industrial settings to ensure safety compliance. This thermic fluid heater is IBR approved, ensuring it meets all safety and regulatory standards applicable in India.Q: How is the fuel consumption determined for these heaters?

A: Fuel consumption depends on the selected capacity and application. Specific consumption rates can be found in the technical brochure or datasheet for each model. It is advisable to consult with the manufacturer for precise details based on your operational parameters.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thermic Fluid Heaters Category

Coal Fired Thermal Fluid Heater

Price 100000 USD ($)

Price Or Price Range INR 5,00,000 to 15,00,000 per unit

Minimum Order Quantity : 1 Unit Piece

Storage / Tankless : Other, Tankless

Installation Type : Other, Industrial Installation

Capacity : 500,000 to 3,000,000 kcal/hr

Thermic Fluid Heater

Price 100000 USD ($)

Price Or Price Range INR 1 Lakh to 10 Lakh / Piece

Minimum Order Quantity : 1 Unit Piece

Storage / Tankless : Storage

Installation Type : Other, Horizontal

Capacity : 50000 Kcal/hr to 2000000 Kcal/hr

Husk Fired Thermal Fluid Heater

Price 100000 USD ($)

Minimum Order Quantity : 1 Unit Piece

Storage / Tankless : Storage

Installation Type : Other, Horizontal

Capacity : 500,000 to 4,000,000 kcal/hr

Wood Fired Thermic Fluid Heater

Price 100000 USD ($)

Price Or Price Range INR 2,50,000 to 15,00,000 per unit

Minimum Order Quantity : 1 Unit Piece

Storage / Tankless : Other, Tankless

Installation Type : Horizontal, Other

Capacity : 100,000 Kcal/hr to 1,000,000 Kcal/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS