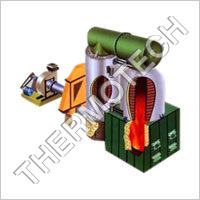

Husk Fired Thermal Fluid Heater

Husk Fired Thermal Fluid Heater Specification

- Type

- Husk Fired Thermal Fluid Heater

- Material

- Mild Steel

- Storage / Tankless

- Storage

- Installation Type

- Horizontal

- Capacity

- 500,000 to 4,000,000 kcal/hr

- Voltage

- 220 V

- Power

- 360,000 kcal/hr

- Dimension (L*W*H)

- 3000 mm x 1300 mm x 1800 mm

- Gas Type

- Solid Fuel (Husk Fired)

- Tank Diameter

- 1200 mm

- Color

- Blue & Silver

Husk Fired Thermal Fluid Heater Trade Information

- Minimum Order Quantity

- 1 Unit Piece

- Main Domestic Market

- Himachal Pradesh, Manipur, Central India, North India, East India, West India, Andhra Pradesh, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Haryana, Jammu and Kashmir, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Mizoram, Meghalaya, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, West Bengal, Andaman and Nicobar Islands, Pondicherry, Nagaland, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, South India, Chhattisgarh, All India

- Certifications

- ISO 9001:2008

About Husk Fired Thermal Fluid Heater

Thermic Fluid Heater Husk Fired

"THERMOTECH" presents innovative vertical four passes THERMOPAC which has Fluidised Bed Combustion (FBC) technology safeguarding comprehensive combustion of even husk fuel and low-grade coal with almost nil wastage and attaining high heat functioning efficiency.

In addition to the prior model TSCV the system is integrated with FBC Technology to safeguard complete combustion,

Help standardized mixing of fuel, uphold unchanging bed temperature, leaves less unburnt fuel with I.D., the dust collector, and F.D. fan for equilibrium draft to safeguard least infiltration of undesirable air through doors and fresh air passes via air pre-heater safeguard all-out fuel to heat operating competence for any profitable grade of solid fuel.

The volume varieties from 2 Lacs to 30 Lacs kcal/hr.

The vertical four pass thermic fluid heater is suitable for Indian industries in quickly changing and unreliable energy condition. The vertical design joined with essential furance offers you a guarantee of valued production on any solid fuel like Wood, Husk, Coal, Bagasee etc.

EFFICIENCY AT ITS PEAK :

- Reduced Excess Air

- Radiant heat exchanger overhead furnace, cools henceforth, less extra air is required. This gives growth to efficiency.

- Air Preheating

- Combustion air from FD fan permits using air preheater to engage the left-over heat from the fuel gases. This outcomes in additional increase in efficacy.

- Balanced Draught System

- This system safeguards least infiltration of undesirable air via fire doors. Henceforth, all the combustion air permits via the APH. Therefore, the supreme heat retrieval from APH takes place, that safeguards rated efficiency.

- Rated Output

- Thermotech's vertical heater model provides you valued efficiency and its considered output.

- Multifuel Option

- The system is appropriate for wood, coal, bagasse etc. for complete production with minor alterations in combustion chamber.

Fuel Consumption calculation grounded on gross calorific value

- Husk: 3100 kcal / kg.

- Steam Coal: 3500 kcal / kg.

Superior Combustion Technology

Our Husk Fired Thermal Fluid Heater boasts a double shell combustion chamber paired with water cooling, ensuring efficient fuel burning and extended equipment life. The water cooling not only enhances safety by absorbing excess heat but also prevents structural damage to the chamber, enabling continuous high-temperature operation.

Efficiency and Control at Its Best

Achieving an operational efficiency between 78% and 82%, this heater maximizes fuel utilization while minimizing emissions. The fully automatic control panel streamlines operation, providing precise regulation of temperature and safety features, thus reducing downtime and enhancing user convenience.

Designed for Diverse Industrial Applications

Meeting the rigorous heating requirements of textile, food, and chemical industries, this horizontal heater delivers consistent heat transfer up to 300C. Its flexible range in capacity and robust mild steel construction make it an ideal choice for varied industrial processes requiring steady, reliable, and safe thermal energy supply.

FAQs of Husk Fired Thermal Fluid Heater:

Q: How does the Husk Fired Thermal Fluid Heater operate and what fuel does it use?

A: This heater operates by burning huska type of solid fuelin a specialized double shell combustion chamber lined with water cooling. The combustion process generates heat, which is transferred via a thermic fluid, providing precise and uniform industrial heating.Q: What are the main benefits of using this heater in industrial environments?

A: Key benefits include high operational efficiency (78%-82%), robust mild steel construction, advanced water-cooled combustion for longevity, and automatic control for safe, convenient use. It effectively supports industrial heating needs in sectors like textiles, food processing, and chemicals.Q: When should I consider installing a Husk Fired Thermal Fluid Heater in my facility?

A: Install this heater when your industrial process demands high-temperature fluid heating (up to 300C) with efficient, eco-friendly fuel use. Its ideal for continuous processes requiring stable and reliable heat supply.Q: Where can the Husk Fired Thermal Fluid Heater be used?

A: This heater is suitable for a variety of industrial facilities across India, especially in sectors such as textiles, food, chemicals, and more, where large-scale process heating is essential.Q: What is the installation process and requirements for this heater?

A: Installation involves positioning the horizontal unit (3000 mm x 1300 mm x 1800 mm) at a facility that can accommodate its size, ensuring solid fuel (husk) storage, electricity (220 V), and safe ventilation. Professional installation ensures optimal water cooling and insulation performance.Q: How is the heat transfer managed and what medium is used?

A: Heat generated from husk combustion is transferred through a thermic fluid, circulating within the system to deliver consistent and regulated heat to industrial processes. The 50 mm glass wool insulation helps minimize heat loss.Q: What distinguishes this heater from conventional systems?

A: Unlike conventional oil or gas-fired heaters, this model utilizes huska renewable and cost-effective fuelwhile maintaining high efficiency and automated operations. Its double shell construction with water cooling offers enhanced durability and safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thermic Fluid Heaters Category

Liquid Fuel Fired Thermic Fluid Heaters

Price Or Price Range 3 Lakh - 30 Lakh / Unit / Milliampere

Minimum Order Quantity : 1 Unit Piece

Installation Type : Other, Vertical / Horizontal

Capacity : 1,00,000 Kcal/hr to 30,00,000 Kcal/hr

Storage / Tankless : Storage

Thermic Fluid Heater

Price 100000 USD ($)

Price Or Price Range INR 1 Lakh to 10 Lakh / Piece

Minimum Order Quantity : 1 Unit Piece

Installation Type : Other, Horizontal

Capacity : 50000 Kcal/hr to 2000000 Kcal/hr

Storage / Tankless : Storage

Coal Fired Thermal Fluid Heater

Price 100000 USD ($)

Price Or Price Range INR 5,00,000 to 15,00,000 per unit

Minimum Order Quantity : 1 Unit Piece

Installation Type : Other, Industrial Installation

Capacity : 500,000 to 3,000,000 kcal/hr

Storage / Tankless : Other, Tankless

Wood Fired Thermic Fluid Heater

Price 100000 USD ($)

Price Or Price Range INR 2,50,000 to 15,00,000 per unit

Minimum Order Quantity : 1 Unit Piece

Installation Type : Horizontal, Other

Capacity : 100,000 Kcal/hr to 1,000,000 Kcal/hr

Storage / Tankless : Other, Tankless

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS