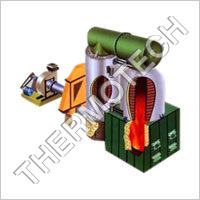

Coal Fired Thermal Fluid Heater

Coal Fired Thermal Fluid Heater Specification

- Type

- Coal Fired Thermal Fluid Heater

- Material

- Mild Steel

- Storage / Tankless

- Tankless

- Installation Type

- Industrial Installation

- Capacity

- 500,000 to 3,000,000 kcal/hr

- Voltage

- 380 V

- Power

- Coal Fuel Fired

- Dimension (L*W*H)

- Varies by Model, approx. 3000x1800x2200 mm

- Gas Type

- Coal

- Color

- Gray / Black

Coal Fired Thermal Fluid Heater Trade Information

- Minimum Order Quantity

- 1 Unit Piece

- Main Domestic Market

- Himachal Pradesh, South India, East India, West India, Assam, Bihar, Chandigarh, Delhi, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, West Bengal, Nagaland, Meghalaya, Arunachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Uttar Pradesh, Haryana, Gujarat, North India, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

- Certifications

- ISO 9001:2008

About Coal Fired Thermal Fluid Heater

Leveraging on our broad industry experience and in-depth market knowledge, we are offering a broad spectrum of Coal Fired Thermal Fluid Heater. The offered heater is best suitable at the situation of rapidly changing and undependable energy situations. Under the proper supervision of our adept professionals, the provided heater is manufactured with high precision by making use of quality approved components with the help of pioneering machinery. Available in various specifications, the offered Coal Fired Thermic Fluid Heater is provided to the clients at affordable prices.

The Coal Fired Thermal Fluid Heater is controlled by the normal coal squares. This heater utilizes a circuitous strategy for heat exchange, by using an oil based liquid as the exchange medium. The provided heater keeps up a steady temperature for the uniform heating. Our offered Coal Fired Thermal Fluid Heater is acclaimed for negligible heat failure to the environment. De-aerator and extension is intended for assurance from thermic liquid oxidation and arrangement of nonstop de-air-circulation of thermic liquid, hence, preventing pump cavitation. In addition the solid and vigorous parts with least handling fans, controls, pump and more are provided in our range.

Features :

- Optimum functionality

- Heat resistance

- Longer service life

- Low maintenance

Thermic Fluid Heater Coal Wood Fired

Horizontal model is better version, which have confirmed their virtuous design and to which new Skills and Substances are added to recover competence to about 93%, simplify the maintenance, energy saving, low smoke release and is able to assimilate with PLC and SCADA system with convenience.

The Stack Heat from

Drain flue gases of Main Heat Exchanger are recovered by means of Combustion Air Pre Heater (CAPH) and fresh combustion air is heated prior to going to burner, which advances combustion competence, reduce fuel consumption, reduces stack temperature, and save environment.

THE COMBUSTION FUELS :

- "THERMOTECH" : Our Thermic Fluid Heaters are combined for all vendible and special fuels obtainable in industry for combustion.

- Fuels like : Diesel / Kerosene / Furnace Oil (HFO) / Light Diesel Oil (LDO-LFO) / Natural Gas / Pipeline N. Gas, LPG / etc. are flammable with same competence, that is thankful to our combustion authorities who designs combustion constraints and Air to fuel proportion for the best production.

Thermic Fluid Heater Coal Wood Fired

"THERMOTECH" presents a novel vertical four passes THERMIC FLUID HEATER is suitable for Indian industries in fast changing and unreliable energy circumstances. The vertical design joined with integral furnace offers you an oath of a valued production on any solid fuel like wood, husk, coal, bagasse, etc. Our generous design assistances in exchange from one fuel to another deprived of negotiating on performance. Its quality promise product comes from THERMOTECH, the corporation recognized for its know-how of heaters and boilers all over India. Nowadays there are more than 1000 THERMOTECH fittings in the country almost in all kinds of industry dipping time and cost.

EFFICIENCY AT ITS PEAK

- Reduced Excess Air

- Radiant heat exchanger above furnace, cools hence, less excess air is needed. This gives rise to efficiency.

- Air Preheating

- Combustion air from FD fan passes through air preheater to absorb the waste heat from the fuel gases. This result in further increase in efficiency.

- Balanced Draught System

- This system ensures minimum infiltration of unwanted air through fire doors. Hence, all the combustion air passes through the APH. Thus the maximum heat recovery from APH takes place, which ensures rated efficiency.

- Rated Output

- Thermotech's vertical heater model gives you rated efficiency & its catagoriesed output.

- Multifuel Option

- The system is suitable for coal, wood, bagasse etc. for full output with minor modifications in combustion chamber.

Fuel Consumption calculation based on gross calorific value

- Steam Coal: 4500 kcal / kg.

- Lignite Coal: 3500 kcal / kg.

- Agro - Waste: 3300 kcal / kg.

Advanced Digital Control and Safety Features

The coal-fired thermal fluid heater comes equipped with a fully automatic digital control panel, enabling precise temperature management and operational monitoring. Key safety measures, such as over-temperature protection and a reliable pressure relief valve, work together to mitigate operational risks, ensuring smooth and secure functionality in demanding industrial settings.

Efficiency and Application Versatility

With an efficiency rating exceeding 80%, this thermal fluid heater delivers optimized energy use, lowering operational costs and fuel consumption. It is widely applicable in sectors such as chemical processing, textiles, and food production, where consistent and controlled heat is critical to maintain quality and productivity.

Customizable and Robust Industrial Design

Constructed from mild steel with a high-temperature-resistant surface, this heater is insulated with 50 mm mineral wool for minimal heat loss. The flue gas outlet can be customized to suit site-specific requirements, while the tankless and modular installation adapts easily to varied industrial plant layouts.

FAQs of Coal Fired Thermal Fluid Heater:

Q: How does the coal-fired thermal fluid heater operate in industrial installations?

A: The heater uses coal as its primary fuel source, heating thermal oil (the heat transfer medium) to deliver reliable heat at up to 300C. The process is controlled by a fully automatic digital panel, supporting industrial-scale operations in sectors such as chemicals, textiles, and food processing.Q: What are the key benefits of using this heater in chemical, textile, and food processing industries?

A: Main advantages include high operational efficiency (above 80%), precise digital control, rapid heat delivery, energy savings, and enhanced safety. Its adaptability and robust construction allow seamless integration into demanding industrial environments.Q: When should over-temperature protection and the pressure relief valve be serviced?

A: Routine maintenance should follow the manufacturers recommended service intervals, commonly before peak production seasons or biannually. Regular inspection ensures that safety features remain effective and the system operates without interruption.Q: Where can the flue gas outlet be positioned during installation?

A: The heaters flue gas outlet is customizable and can be configured according to the sites ventilation and safety requirements. This flexibility allows optimal placement for efficient exhaust gas management and compliance with onsite regulations.Q: What is the process for fueling the thermal fluid heater?

A: Fuel is supplied either manually or through a stoker conveyor system, as preferred by the operator. Coal is fed into the combustion chamber, where it heats the thermal oil, which then circulates through the system to provide continuous heat transfer.Q: How does the insulation contribute to the heaters performance?

A: A 50 mm layer of mineral wool insulation envelops the heater, significantly reducing heat loss and enhancing thermal efficiency. This supports sustained high performance while minimizing energy waste and external temperature exposure.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thermic Fluid Heaters Category

Liquid Fuel Fired Thermic Fluid Heaters

Price Or Price Range 3 Lakh - 30 Lakh / Unit / Milliampere

Minimum Order Quantity : 1 Unit Piece

Type : Other, Liquid Fuel Fired Thermic Fluid Heater

Color : Black / Blue / Custom

Installation Type : Other, Vertical / Horizontal

Thermic Fluid Heater

Price Or Price Range INR 1 Lakh to 10 Lakh / Piece

Price 100000 USD ($)

Minimum Order Quantity : 1 Unit Piece

Type : Other, Thermic Fluid Heater

Color : Blue / Grey / Customized

Installation Type : Other, Horizontal

Husk Fired Thermal Fluid Heater

Price 100000 USD ($)

Minimum Order Quantity : 1 Unit Piece

Type : Other, Husk Fired Thermal Fluid Heater

Color : Blue & Silver

Installation Type : Other, Horizontal

Wood Fired Thermic Fluid Heater

Price Or Price Range INR 2,50,000 to 15,00,000 per unit

Price 100000 USD ($)

Minimum Order Quantity : 1 Unit Piece

Type : Other, Wood Fired Thermic Fluid Heater

Color : Industrial Black with Red/Brown Accents

Installation Type : Horizontal, Other

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free