Thermic Fluid Heater

Thermic Fluid Heater Specification

- Type

- Thermic Fluid Heater

- Material

- Mild Steel

- Storage / Tankless

- Storage

- Installation Type

- Horizontal

- Capacity

- 50000 Kcal/hr to 2000000 Kcal/hr

- Voltage

- 380 V

- Power

- Diesel / Gas / Solid Fuel Fired

- Dimension (L*W*H)

- Customized as per Model

- Tank Diameter

- Varies as per Capacity

- Color

- Blue / Grey / Customized

Thermic Fluid Heater Trade Information

- Minimum Order Quantity

- 1 Unit Piece

- Main Domestic Market

- Himachal Pradesh, , South India, North India, East India, West India, Assam, Arunachal Pradesh, Bihar, Chandigarh, Delhi, Gujarat, Goa, Jammu and Kashmir, Jharkhand, Karnataka, Madhya Pradesh, Maharashtra, Mizoram, Manipur, Punjab, Rajasthan, Sikkim, Tamil Nadu, Tripura, West Bengal, Nagaland, Uttar Pradesh, Meghalaya, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Dadra and Nagar Haveli, Lakshadweep, Haryana, Telangana, Andhra Pradesh, Kerala, Central India, Odisha, Chhattisgarh, All India

- Certifications

- ISO 9001:2008

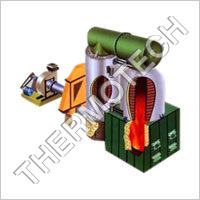

About Thermic Fluid Heater

We are highly specialized in manufacturing, exporting and supplying a qualitative assortment of Thermic Fluid Heater. It is an operation to transfer heat by the fluids under the well suitable temperature. The provided heater is efficiently manufactured under the stem guidance of our skilled professionals as per the set industry norms for ensuring longer service life as the users end. Moreover, the offered Thermic Fluid Heater is available in numerous specifications as per the application requirements of the clients.

Salient Features of this Model

- Furnace is manufactured for multi fuel choices, with main thrust on appropriate choice of furnace height, combustion grate, fuel feeding systems and combustion volume. To safeguard effectual combustion and minor heat loss.

- Coils are made with the finest flow deliberation to gain supreme heat from flue gases. Coils are verified at 3 steps prior to final delivery as a part of Thermotech rigorous quality regulation.

- FD Fan, ID Fan, & booster fan are designated as per fuel faultless air-fuel ratio prerequisite, that guarantees best air amount for combustion and therefore protects power consumption.

- Expansion Tank capacity is explicitly chosen following consulting entire holdup of Thermic Oil. DE aeration Tank is particularly designed seeing flow and temperature obligation.

- Thermotech provides comprehensive solution of Thermic Fluid heating system including Pollution control equipment, Pipeline, fuel treatment, etc on Turnkey basis.

Auto Controls & Safety

- Thermic Fluid Temperature control

- Cut-off of ID/FD fan of predetermined temperature and resume of predetermined temperature and resume of preset difference temperature to uphold system temperature is done via Digital temperature indicator-cum-controller.

- Stack Temperature Control

- Cut off of ID/FD fan and alarm is sounded by a blind temperature controller in case stack temperature surpasses to predetermined temperature.

- Low/NO Flow of Thermic Fluid

- Difference pressure switch associated crosswise intel and exit headers signs low flow alarm when low fluid pressure occurs of Thermic fluid in coils.

- Low Level of Thermic Fluid

- The visual level pointer and float activated lever switch installed in expansion tank signs alarm when low level thermic fluid occurs in the system.

- Thermic Fluid Pump Motor Trip

- In case of electrical interlocks, thermic fluid pump motor trip, cut off ID/FD fan.

- Power Failure

- Diesel engine drive saves thermic fluid affecting the system to stop its dilapidation and overflow.

- Excess Furnace Bed Temperature

- Digital temperature indicator-cum-controller wits furnace bed temperature and immediately cut off ID/FD fan overhead set value(for FBC unit).

Benefits :

- Multi-Fuel Option

- Energy Optimization

- Less Power Consumption

- Low Maintenance

Features :

- Effortless operation

- Lengthier functional life

- Rough design

- Completely automatic

Advanced Thermal Efficiency for Industrial Demands

Engineered with modern heat exchange technologies, our Thermic Fluid Heater optimizes fuel usage and achieves thermal efficiencies as high as 87%. This ensures cost-effective energy performance and consistent high-temperature output, critical for industries like food processing and pharmaceuticals where precision heating is paramount. The automatic or manual firing modes grant adaptability for varied operational requirements, providing both flexibility and enhanced process control.

Versatile Applications and Reliable Operation

With a wide capacity range and customizable dimensions, this thermic fluid heater seamlessly serves major industrial sectors, including textile, pharmaceutical, and food processing. The horizontal installation and storage-based design facilitate ease of integration into new or existing setups. Multiple heat exchanger options and advanced control functionalities support dependable, around-the-clock heating, minimizing downtime and maximizing productivity.

FAQs of Thermic Fluid Heater:

Q: How does the thermic fluid heater achieve up to 87% thermal efficiency?

A: The heater leverages advanced shell-and-tube or coil-type heat exchangers, optimized combustion design, and precise control via its fully automatic digital panel, which collectively minimize heat losses and ensure maximum energy transfer, achieving thermal efficiency rates up to 87%.Q: What fuel options can be used with this thermic fluid heater?

A: This heater is compatible with diesel, gas, and solid fuels, offering flexibility to choose the most appropriate and cost-effective fuel type for your specific industrial heating application.Q: When should a fully automatic control panel be used?

A: A fully automatic control panel is ideal for operations requiring minimal manual intervention, continuous monitoring, and enhanced safety, such as in pharmaceutical or food processing environments where precise temperature and operational control are critical.Q: Where can this thermic fluid heater be installed?

A: Designed for horizontal installation and customizable in dimensions, the heater can be installed in a wide variety of industrial settings, including textile, food processing, and pharmaceutical facilities throughout India.Q: What is the process for integrating this heater into an industrial system?

A: Integration involves site assessment for installation, adapting tank diameter and unit dimensions to match system requirements, connecting the heater to the process loop, and configuring the control panel for desired firing and temperature settings.Q: How is the thermic fluid heater beneficial for industrial applications?

A: With rapid and efficient heat transfer, customizable design, broad application range, and advanced automatic controls, the heater significantly improves process consistency, energy efficiency, and overall operational safety in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thermic Fluid Heaters Category

Liquid Fuel Fired Thermic Fluid Heaters

Price Or Price Range 3 Lakh - 30 Lakh / Unit / Milliampere

Minimum Order Quantity : 1 Unit Piece

Power : Diesel / Furnace Oil / LDO

Installation Type : Other, Vertical / Horizontal

Capacity : 1,00,000 Kcal/hr to 30,00,000 Kcal/hr

Husk Fired Thermal Fluid Heater

Price 100000 USD ($)

Minimum Order Quantity : 1 Unit Piece

Power : 360,000 kcal/hr

Installation Type : Other, Horizontal

Capacity : 500,000 to 4,000,000 kcal/hr

Coal Fired Thermal Fluid Heater

Price Or Price Range INR 5,00,000 to 15,00,000 per unit

Price 100000 USD ($)

Minimum Order Quantity : 1 Unit Piece

Power : Coal Fuel Fired

Installation Type : Other, Industrial Installation

Capacity : 500,000 to 3,000,000 kcal/hr

Wood Fired Thermic Fluid Heater

Price Or Price Range INR 2,50,000 to 15,00,000 per unit

Price 100000 USD ($)

Minimum Order Quantity : 1 Unit Piece

Power : Wood Fired (No Electric Power)

Installation Type : Horizontal, Other

Capacity : 100,000 Kcal/hr to 1,000,000 Kcal/hr

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS